Processing capacity: 15-200t/h

Feeding size: 125-250mm

Feed opening: 150×250-300×1300mm

Motor power: 5.5-55kw

Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

Sand washer is a highly efficient sand washing machine researched and manufactured by adopting advanced technology and combing with the actual condition in domestic sand and stone industry. Sand washing plant produced by our company has the advantages of high cleanness, reasonable structure and high output. In the sand washing process, the amount of sand that is washed away is small. In addition, the transmission part is separated from water and sand, so that the failure rate is much lower than that commonly used sand washing equipment, and it has become the optimum option for upgrading and updating of domestic sand washing industry.

This series of sand washer can wash and separate the stone powder and mud in the sand and stone. The novel leak-proof structure, adjustable down-flow weir board and reliable transmission device ensure the excellent washing and dehydration effect. This equipment has the functions of washing, dehydration and classification and has the features of high washing ratio, reasonable structure, big processing capacity, low power consumption and low drain of sand in the washing process. Especially its transmission device is separated from water and sand, so that its failure rate is much lower than common sand washing machine and it is the best choice for upgrading and updating of sand washer in domestic sand washing machine industry.

Sand washing machine can also be called screw washing machine, which has the outstanding features of simple structure, stable operation, high washing ratio and high output. It is widely used in construction site, sand and stone plant, glass plant, power station, concrete station and other industrial departments.

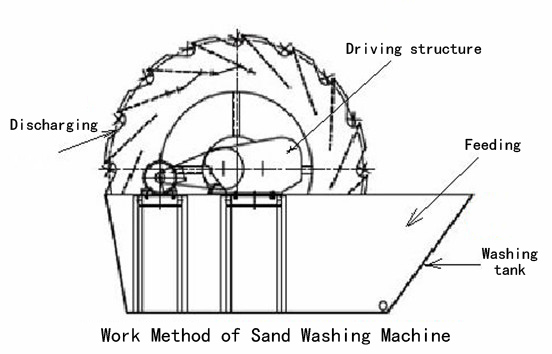

When sand washer works, the power plant drives the impeller to slowly rotate after slowing down through the V-shaped belt, reducer and gear, and sand and stone materials go into the washing chute from the material cabin, and roll driven by the impeller and grind with each other to remove the impurities covering the surface of the sand and stone materials, and at the same time break the moisture layer coated on the sand particles for the purpose of dehydration. In the meantime, add water in it to form a strong water flow to timely wash away the impurities and foreign matters with small proportion and discharge them from the overflow port to complete the washing process.

If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days. We promise that all your informations won't be leaked to anyone. Or call us on +0086-371-67833161.

We always serve customers with heart and soul.