Processing ability: 0.5–500 t/h

Feeding size: ≤25 mm

Applied material: cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mills are widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry.

For over 20 years, Hongxing Machinery has been dedicated in the research of ore beneficiation technology and our company is a professional company manufacturing all types of grinding mills, including Chinaware ball mill, energy saving ball mill, small-sized ball mill, coal mill, ball grinder, rod mill and cement ball mill.

Ball mill is suitable for grinding all kinds of ores and other materials in ore beneficiation, building material and chemistry and the grinding types can be divided into dry type and wet type. According to the ore discharging manners, ball mills can be divided into lattice type and overflow type. Hongxing ball mill changes the structure of traditional ball mill and the machine frame and the chassis are integrated, so that it can be installed on the basic plane for one time. The principal axis adopts biserial self-aligning roller bearing, which reduces the energy consumption by 30%, improves the granularity and processing capacity by 15%-20%.

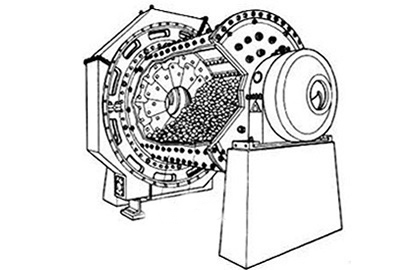

Ball mill grinder is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. The hollow shaft uses steel casting, the inner lining can be dismantled and changed, and the rotary rack wheel uses casting gear hobbing and inside the cylinder there is wear-resisting lining board which has fine abrasion performance. This machine has stable operation and reliable performance.

According to the material types and the ore discharging methods, it can be divided into dry type ball mill and wet type lattice ball mill.

This machine is a horizontal type cylinder rotary device and outside the cylinder there is drive gear which drives the cylinder to rotate during the working process. Materials spirally and evenly go into the first cabin of the grinding machine through the feeding hollow shaft from the feeding device, and inside the first cabin, there are ladder lining boards or ripple lining board in which there are many grinding balls with different specifications. The cylinder rotates and produces eccentric force to bring the steel balls to a certain height, and then the steel balls will fall down to impact and grind the materials. After being coarsely ground in the first cabin, the materials will go through the single-layer partition board and into the secondary cabin in which there are flat lining board, and in the lining board there are grinding balls to further grind the materials. Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding process.

If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days. We promise that all your informations won't be leaked to anyone. Or call us on +0086-371-67833161.

We always serve customers with heart and soul.