Processing capacity: 12-1000t/h

Discharge opening: 3-60mm

Feeding size: 35-300mm

Motor power: 30-280kw

Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

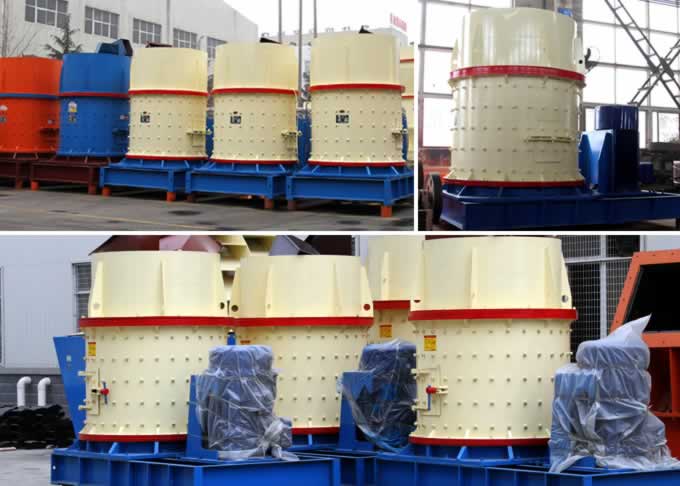

Compound crusher, which can also be called combination crusher, is a new type of crushing machine researched, developed and manufactured by our company on the basis of optimizing the main technical parameters and improving the structural property of traditional crushing machine according to the actual condition and the customers’ needs. It is mainly used for crushing stones.

Compound crusher, which can also be called combination crusher, is one of the commonly used machines in stone production line and sand making production line. Compound crusher is adjustable fine crushing machine without grating bar, and it can be widely used for the fine crushing of raw materials and clinker in cement plant, at the same time, it is also suitable for the fine crushing of medium hard materials such as dolomite, flint clay, lead zinc ore, serpentine ore, blast furnace slag and phosphate ore and especially suitable for making sand with hard limestone, dolomite, granite and basalt and processing and crushing roadbed stone materials for highway.

.jpg)

.jpg)

The combination crusher manufactured by our company is suitable for the fine crushing of limestone, clinker, coal and other types of ores in building material, mining and chemistry, also for the fine crushing of materials with medium hardness such as dolomite, flint clay, lead-zinc ore, serpentine, blast furnace slag, coal gangue and phosphate ore. It is especially suitable for the artificial sand making with hard limestone, dolomite, granite and basalt and for the processing and crushing of stone materials for highway. The compression strength of the materials to be crushed should not exceed 140MPa and the humidity should not be higher than 15%.

1. Big crushing ratio

2. High output, 1.4 times higher than that of the same type of product in domestic market

3. High efficiency and energy conservancy

4. The quick-wear parts adopt high hardness, high tenacity and multi-component alloy wear-resisting materials, so that the service of the equipment is improved by 2-3 times.

5. The gap between hammers and impact plates are adjustable, thus satisfying various granularity requirements.

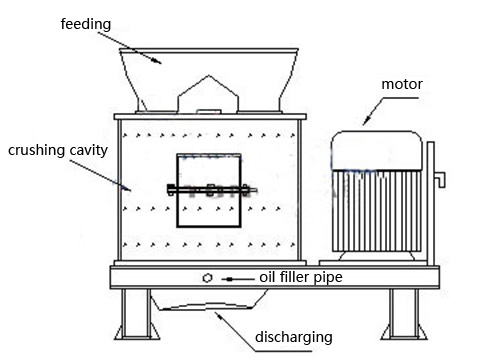

Massive ores vertically fall from the upper part of China compound crusher to the impeller rotating with high speed, and under the eccentric force, the materials will have high-speed hit and crush with the materials that flow around the impeller in the form of umbrella. After the materials hit with each other, they will hit, abrade and be crushed in the space between impeller and machine shell, and finally the materials will be discharged from the bottom of the machine, thus forming a closed-circuit cycle. The granularity of final products will be controlled by the screening equipment.

(1) Simple and reasonable structure and low running cost. The adoption of “stone impacting stone” principle lowers the abrasion.

(2) High crushing efficiency and energy conservancy.

(3) Endowed with the functions of coarse crushing and coarse grinding.

(4) Seldom influenced by the water content of the materials and the water content can reach about 8%.

(5) Working noises are lower than 75db and the powder dust pollution is little.

(6) Suitable for crushing materials with medium hardness and super hardess.

(7) Cubic particle shape, big bulk density and little iron pollution.

(8) Small abrasion of the lining board and convenient maintenance.

If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days. We promise that all your informations won't be leaked to anyone. Or call us on +0086-371-67833161.

We always serve customers with heart and soul.